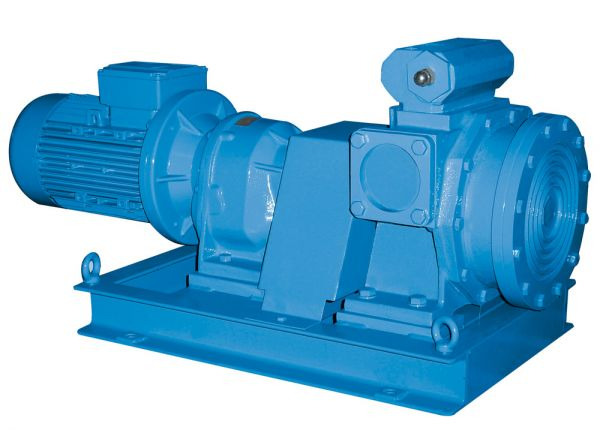

P Pompe a disco cavo oscillante

USI E CAMPI DI APPLICAZIONE

La particolare realizzazione delle pompe P permette di impiegarle in vari settori come quello navale, chimico e petrolchimico, cartario, alimentare, vernici, ecc., pompando i liquidi più diversi, da quelli viscosi e lubrificanti a quelli acquosi, fluidi parzialmente abrasivi, fluidi aggressivi, ecc..

AUTOADESCANTI

Le pompe P sono autoadescanti, cioè possono adescarsi automaticamente anche con tubazione aspirante vuota e senza valvola di fondo. La capacità di adescamento dipende da come viene realizzata la tubazione di aspirazione e dal liquido pompato.

REVERSIBILI

Le pompe P sono perfettamente reversibili, cioè mantengono invariate le proprie caratteristiche di portata e prevalenza, pompando sia in un senso sia nell'altro, semplicemente invertendo il senso di rotazione del motore.

BASSO NUMERO DI GIRI

Le pompe P possono avere un numero di giri max. intorno ai 480 rpm, cioè l'albero della pompa, i suoi cuscinetti, la girante con il dispositivo elastico al massimo ruotano a 480 rpm. Il basso numero di giri e le pochissime parti in movimento garantiscono un lungo funzionamento con le stesse prestazioni e garanzie di affidabilità per la pompa ed il relativo impianto. La velocità ridotta è ottenuta tramite un riduttore montato tra pompa e motore.

ECCENTRICITÀ ELASTICA DEL DISCO POMPANTE

Il disco cavo oscillante equilibrato è mantenuto a contatto del corpo pompa attraverso un dispositivo elastico (molla + scodellino). Tale dispositivo consente il passaggio di particelle solide ed il recupero dei giochi dovuti all'usura mantenendo costanti nel tempo le caratteristiche di portata e prevalenza della pompa anche con i fluidi viscosi, aggressivi ed abrasivi. Il disco cavo è imperniato in modo eccentrico rispetto all'albero della pompa ed è guidato dal diaframma che separa la bocca di aspirazione da quella di mandata. La rotazione dell'albero trascina in un movimento oscillante il disco cavo, il quale si mantiene sempre tangente alle due superfici cilindriche, esterna ed interna, secondo due generatrici diametralmente opposte, formando così due tenute idrauliche mobili.